Development of an application using excel for design of a double rotor axial flux motor YouTube

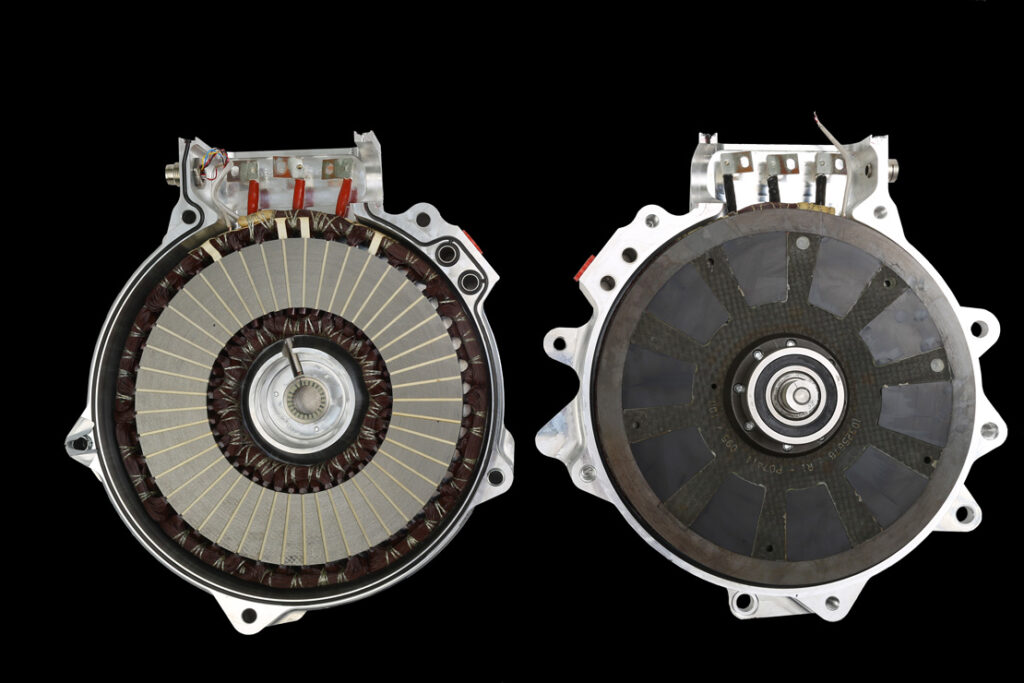

This paper proposed a new external-rotor yokeless and segmented armature axial flux machine applied in-wheel traction. The loss analysis for the motor cooling casing is performed based on finite-element method, and the height of the cooling fins is optimized to decrease the eddy current loss and increase the efficiency of the motor. Subsequently, epoxy potting is developed to increase the heat.

This AxialFlux Motor With a PCB Stator Is Ripe for an Electrified World IEEE Spectrum

. In radial flux motors, retention of the magnets against centrifugal force on the rotor is required but there is no such requirement in axial flux motors. Some important features of.

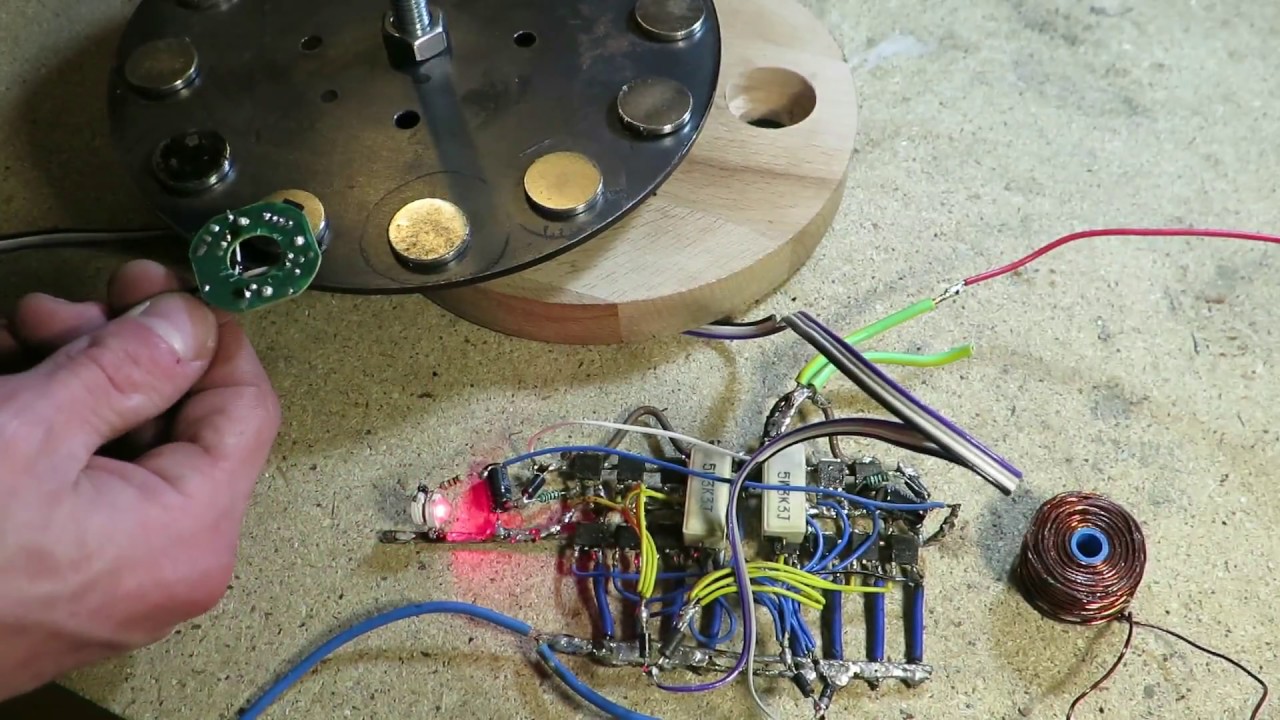

Custom axial flux permanent BLDC Ultra light electric motor

Abstract: This paper presents a comparison of two different kinds of BLDC-Motors for application in handheld power tool drives. Whereas radial flux machines are well known and broadly used, the axial flux concept is less popular. One reason may be the more complex design process and the need to use 3D-FEM calculation.

(V51),Using new technology in axial flux bldc motor. YouTube

The proposed solution is to design an ironless, axial or radial flux, electric BLDC motor, which would provide the high efficiency and power density needed, along with axial modularity and fault-tolerance [2]. The design can be rapidly constructed through the process of 3D printing.

Design HMI Axial Flux Motor

The aim of this paper is to develop a methodology to design an axial flux permanent magnet brushless direct current (AFPM) motor for a washing machine and compare the results with a conventional radial flux permanent magnet brushless direct current (RFPM) motor with the same power ratings. The AFPM motor is designed based on the maximum power density for an optimum inner-to-outer diameter.

Axial Flux BLDC Motor Design Course YouTube

(June 2023) A motor can be built upon any flat structure, such as a PCB, by adding coils and a bearing. The coil winding process and the process of joining the coil and core may be simpler. Since the coils are flat, rectangular copper strips can more easily be used, simplifying high-current windings.

Axial flux motors EMobility Engineering

Citations: 1 Sections PDF Tools Share Abstract The present study investigated the design, simulation, and manufacturing of a new coreless stator axial-flux permanent-magnet motor.

DIY BLDC Axial Motor YouTube

Corpus ID: 56358747 Axial flux PM BLDC motor design methodology and comparison with a radial flux PM BLDC motor E. Yeşilbağ, Y. Ertuğrul, L. T. Ergene Published in Turkish J. Electr. Eng… 30 July 2017 Engineering Turkish J. Electr. Eng. Comput. Sci. TLDR

Axial flux motors EMobility Engineering

Final Version: 30.07.2017. Abstract: The aim of this paper is to develop a methodology to design an axial ux permanent magnet brushless direct current AFPM motor for a washing machine and compare the results with a conventional radial ux permanent. magnet brushless direct current RFPM motor with the same power ratings.

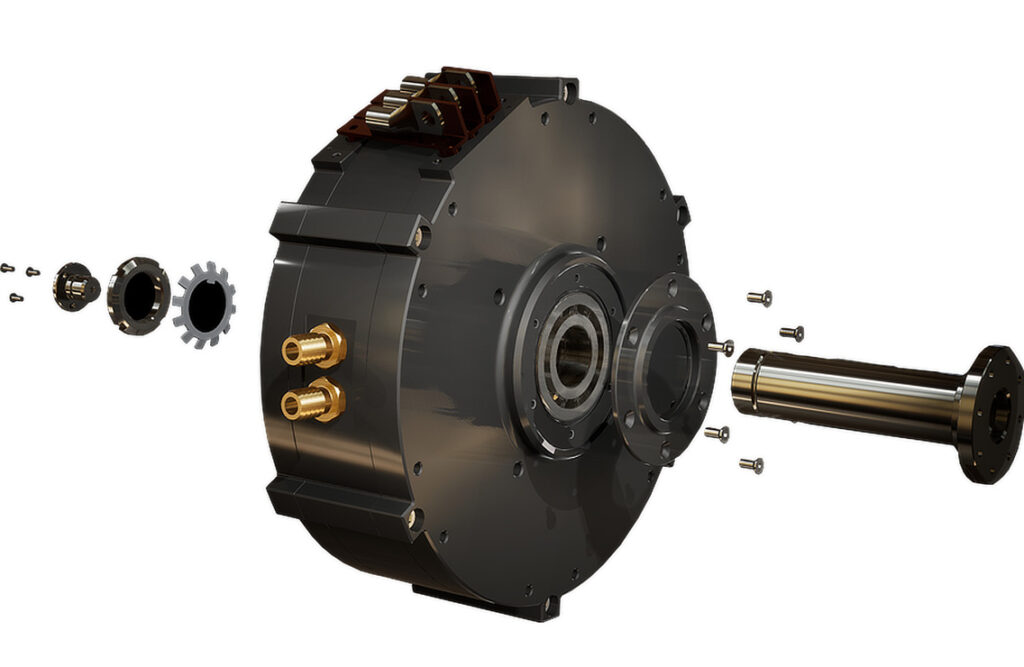

Belgian startup Magnax designs new axial flux rotor for electric vehicles iMotorbike News

This paper presents a comparison of two different kinds of BLDC-Motors for application in handheld power tool drives. Whereas radial flux machines are well known and broadly used, the axial flux concept is less popular. One reason may be the more complex design process and the need to use 3D-FEM calculation.

Design and construction of new axial‐flux permanent motor Alamdar Yazdi 2020 IET

In this paper, an axial flux brush less DC motor is chosen for the study. A preliminary design is arrived based on the magnetic circuit and power balance equations. Then the Finite Element Analysis of the preliminary design is carried out. It is found from the FEA that the preliminary design can be refined.

What Is An Axial Flux Motor And Why Is It Better? Ripple Software Consulting

The Axial Flux BLDC motors are relatively new, specially at higher power ratings over 10 kW. Therefore the designers face a lot of difficulties in designing and optimizing the motor for a given application. This paper presents a new method to optimize the performance in speed, torque, torque stability, power output, power density and motor dimensions in view of the cost and reliability for a.

Design HMI Axial Flux Motor

This paper presented design of 5 kW axial flux permanent magnet of BLDC motor based on Solidwork and Ansys Maxwell. The motor parameters were designed by modeling of physical parameters through calculation, such as number of pole, stator core diameter, and selection of material type.

(V108),Powerful axial flux bldc motor using dual rotor and dual coil. YouTube

Software design tool for optimum Axial Flux BLDC motors DOI: 10.1109/ICIINFS.2009.5429806 Authors: J. W. K. Kosala Jayasundara University of Moratuwa R. Munasinghe University of Moratuwa Abstract.

3D printed axial flux BLDC motor YouTube

Software design tool for optimum Axial Flux BLDC motors Abstract: The Axial Flux BLDC motors are relatively new, specially at higher power ratings over 10 kW. Therefore the designers face a lot of difficulties in designing and optimizing the motor for a given application.

Axial flux motors EMobility Engineering

Stepper motors are employed in a wide range of consumer and industrial applications.. F. Analyzing the profile effects of the various magnet shapes in axial flux PM motors by means of 3D-FEA. Electronics 2018, 7, 13. G.F.; Li, H.W. Design of stepper motor position control system based on DSP. In Proceedings of the 2017 2nd International.